Low price for Casting Type Nylon Film /Bopa Film - Bio-based BOPLA(Biaxially Oriented Polylactic Acid)Film – Changshu

Low price for Casting Type Nylon Film /Bopa Film - Bio-based BOPLA(Biaxially Oriented Polylactic Acid)Film – Changshu Detail:

PLA (polylactic acid) is a polymer with lactic acid produced by biological fermentation as the main raw material. Its raw material is sufficient and can be regenerated, the product is biodegradable. After being used, it can be composed into carbon dioxide and water at a temperature higher than 55 ℃ or under the action of oxygen enrichment and microorganism, realizing the material circulation in nature with little impact on the environment, Therefore, it is an ideal green polymer material.

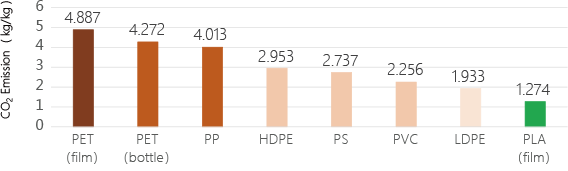

Compared with other processing methods, biaxial tensile process gives PLA material higher strength and thinner film thickness, which makes the process of material disintegration and microbial erosion easier, so it can greatly shorten the biodegradation time of the material. Compared with traditional fossil based polymers, PLA has reliable biosafety, biodegradability and can reduce energy dependence. Since PLA comes from bio base, it has a significant effect on carbon reduction, and carbon emissions are reduced by more than 68% compared with traditional fossil-based plastics.

Click the picture to view more product information

Date from Plastic Europe: Comparison of carbon dioxide emission in polymer production process

·BOPLA has good biocompatibility and degradation performance, which is environmental friendly.

· Excellent processing performance and good folding stability and twisting retention.

· High transparency, low haze, good surface gloss and excellent printing performance.

· Good heat-sealing performance without additional treatment.

The biaxial stretching process can greatly improve the mechanical properties of PLA film, and further expand its application fields. It can be used in tape, food packaging, fresh packaging, paper laminating, release material and other fields, which is of great significance for packaging reduction, environmental protection and carbon reduction.

Click the picture to view more product application information

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for Low price for Casting Type Nylon Film /Bopa Film - Bio-based BOPLA(Biaxially Oriented Polylactic Acid)Film – Changshu , The product will supply to all over the world, such as: Bandung , United States , Irish , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.