The manufacturing technologies of nylon film include CPA, IPA and BOPA.

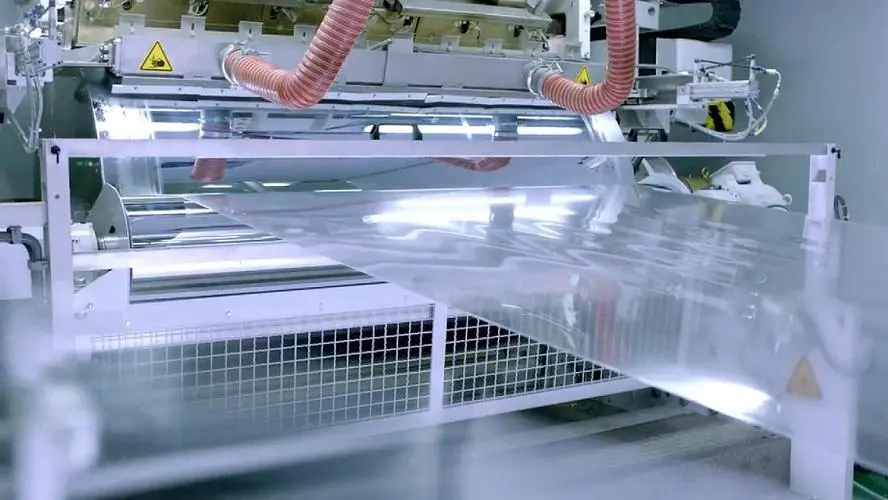

The most widely used and efficient method is the BOPA (biaxially oriented polyamide), whose production process has two types: Sequential stretching production technology and simultaneously stretching method.

Sequential stretching Production Technology

The Sequential stretching production technology is also called two steps method, that is, stretching in TD direction firstly, and then in MD direction, so that the film has high mechanical strength. However, due to the limitations of equipment and two-step production technology, the film is easy to have bow effect, resulting in uneven phenomenon in the film, that is, the middle position of the large film in the same roll has a better material performance, which can be used for the product required multi-colors printing, frame patching and retort, while the film roll at the two sides are more suitable for simple printing and lamination.

Simultaneously Stretching Technology

Simultaneously stretching technology is stretching in MD direction and TD direction at the same time that requires pre-treatment with water bath prior to stretching. This production technology is able to reduce the “bow effect” of the film to a large extent and improves the balance of the product, and also reduces the moisture absorption of the film. The simultaneously stretching technology includes mechanical synchronous stretching technology and LISIM technology.

Because the stretching track of mechanical synchronous stretching is fixed, the stretching ratio cannot be adjusted and the mechanical strength of the produced products is smaller accordingly.

While the LISIM technology is the most advanced BOPA film production technology in the world, which overcomes the defect of fixed mechanical synchronous stretching track. In the stretching stage, as each chain clamp is controlled by a separate linear motor, its stretching track can be adjusted automatically and intelligently. The products produced have high mechanical strength and good balance, combinating the advantages of both two-step production technology and mechanical synchronous stretching technology.

Post time: Feb-16-2022