Introduction to biaxially oriented polylactic acid BOPLA

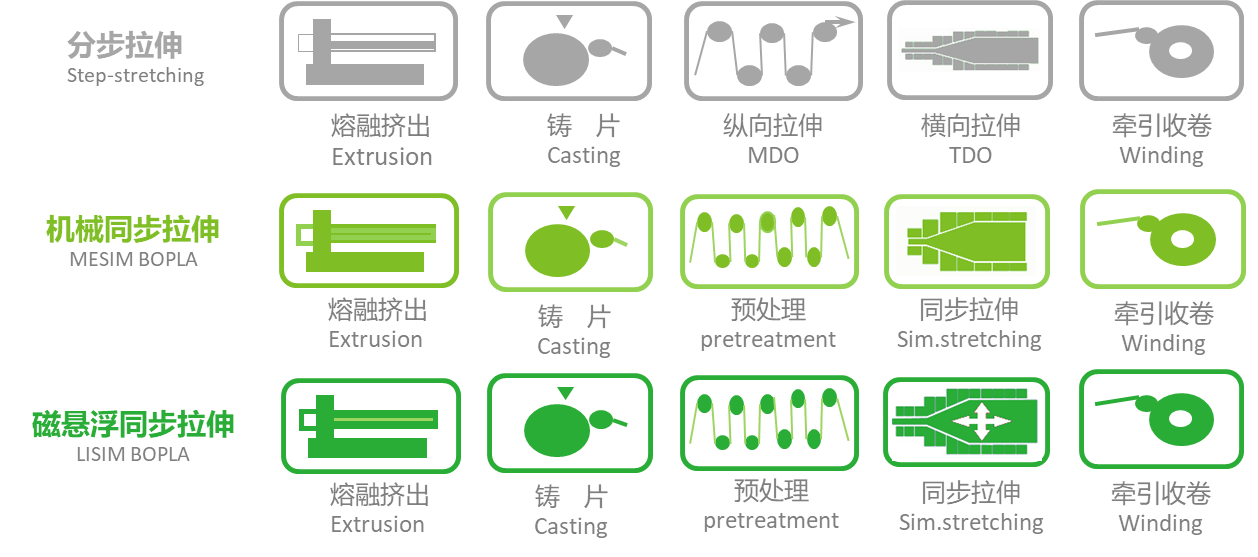

Biaxially oriented poly (lactic acid) film (BOPLA) is a kind of high-strength bio-based film material obtained after longitudinal and transverse stretching of polylactic acid material and crystallization. Biaxial stretching process includes Step-stretching, 2. Mechanical simultaneous stretching and m LISIM simultaneous stretching, as shown in Figure 1. Compared with other processing methods, the biaxial stretching process promotes the molecular orientation of PLA materials, endows PLA materials with high strength and high heat resistance, and reduces the thickness of products to achieve the best utilization of materials. BOPLA has the advantages of balanced vertical and horizontal mechanical properties, high transparency, high permeability and good printability. It can widely replace the film currently used in e-commerce logistics, high-end food, electronic products, paper-plastic lamination and other fields.

Figure 1. Diagram of biaxial stretching process

BOPLA has three advantages in market application.

First, BOPLA is the most promising bio-based transparent film on the market. Thanks to the material characteristics and machinability of PLA, BOPLA has fewer production steps and less processing difficulty, and has the advantages of waterproofing and printability of traditional polymer film, which makes it have a great prospect in the field of thin film application

Second, BOPLA has controllable degradation characteristics. Under conventional storage conditions, BOPLA can maintain good performance to guarantee the shelf life of products and avoid shortening the shelf life of terminal products due to excessive degradation speed. Under compost conditions, BOPLA can achieve thinner film thickness under the same mechanical properties, so that it can degrade rapidly in compost environment.

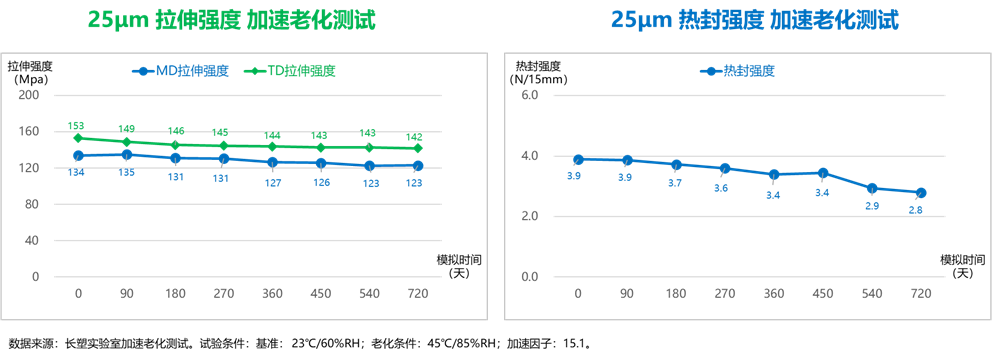

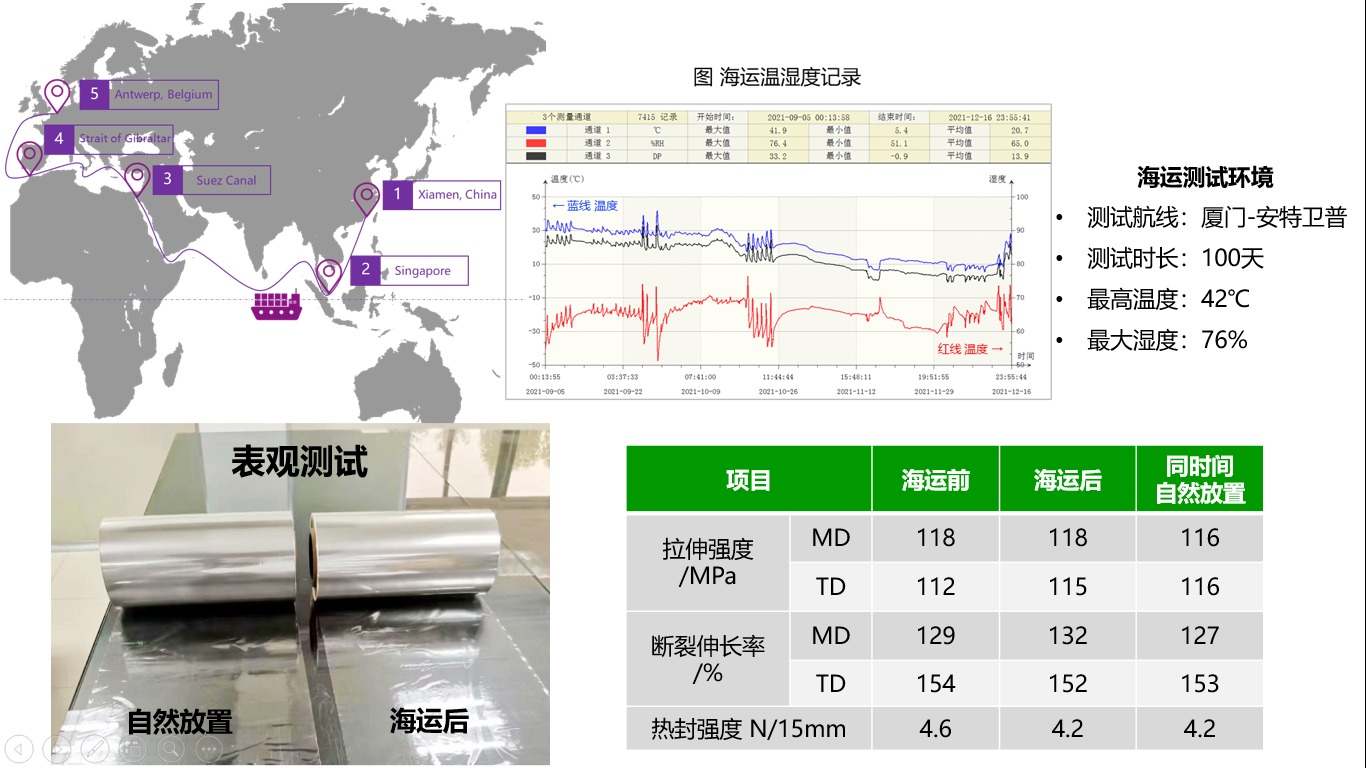

Third, BOPLA meets the requirements of conventional warehousing and logistics transportation, and has the basis of industrial application. In BOPLA's accelerated aging test (FIG.2), tensile strength decays only 4.5% after 1 year and 5.2% after 2 years. The heat sealing strength attenuates 12.8% after 1 year, which meets the requirements of heat sealing performance. In the BOPLA sea tests (Xiamen-Antwerp, FIG. 3), there was no significant change in film properties and appearance.

Figure 2. BOPLA accelerated aging test

Figure 3. BOPLA Marine test

The characteristics of BOPLA products are shown in Table 1.

Table 1. Product characteristics table

|

number |

Test Item |

Units |

BiONLY ®ESL |

Competitive product A |

|

|

1 |

Thickness |

um |

40 |

40 |

|

|

2 |

Tensile strength |

MD |

Mpa |

119 |

99 |

|

TD |

164 |

159 |

|||

|

3 |

Tensile modulus |

MD |

Mpa |

3833 |

3207 |

|

TD |

4490 |

4347 |

|||

|

4 |

Elongation at break |

MD |

% |

138 |

185 |

|

TD |

108 |

91 |

|||

|

5 |

(100℃/10min)Heat Shrinkage |

MD |

% |

4 |

4.3 |

|

TD |

0.2 |

6.9 |

|||

|

6 |

Haze |

% |

1.02 |

1.71 |

|

|

7 |

Transmission Rate |

% |

94.8 |

95.2 |

|

|

8 |

Gloss(angle 45°) |

% |

83.6 |

81.6 |

|

|

9 |

Moisture tensile |

Treat side |

mN/m |

43 |

37 |

|

Untreated side |

35 |

34 |

|||

|

10 |

Heat sealing strength (85℃/3s) |

N/15mm |

6.3 |

6.3 |

|

BiONLY ® is a BOPLA film independently developed by Xiamen Changsu Industry Co., Ltd.

classification of BiONLY

|

Product model |

Application field |

Specifications |

|||

|

Thickness/μm |

Corona |

Treatment |

Width/mm |

||

|

Standard type |

Suitable for common printing and gluing products such as tapes and labels |

15-40 |

One-sided corona |

non |

300-2100 |

|

Lamination type |

Suitable for coating, lamination and other processes |

15-40 |

non |

Single and double-sided processing |

300-2100 |

|

Heat sealing type |

Suitable for printing and heat sealing bags |

15-40 |

One-sided corona |

Single and double-sided heat sealing |

300-2100 |

Post time: Feb-09-2023